AISI SAE 8617H الأنابيب الفولاذية الدقيقة ذات الصلابة المنخفضة للمحامل

1. نظرة عامة على المواد

AISI/SAE 8617H (UNS H86170) عبارة عن فولاذ مقوى مصنوع من سبائك النيكل والكروم والموليبدينوم منخفض الكربون. إنه مصمم لتوفير طبقة سطحية شديدة الصلابة ومقاومة للاهتراء بعد الكربنة مع الحفاظ على قلب قوي ومقاوم للتعب.

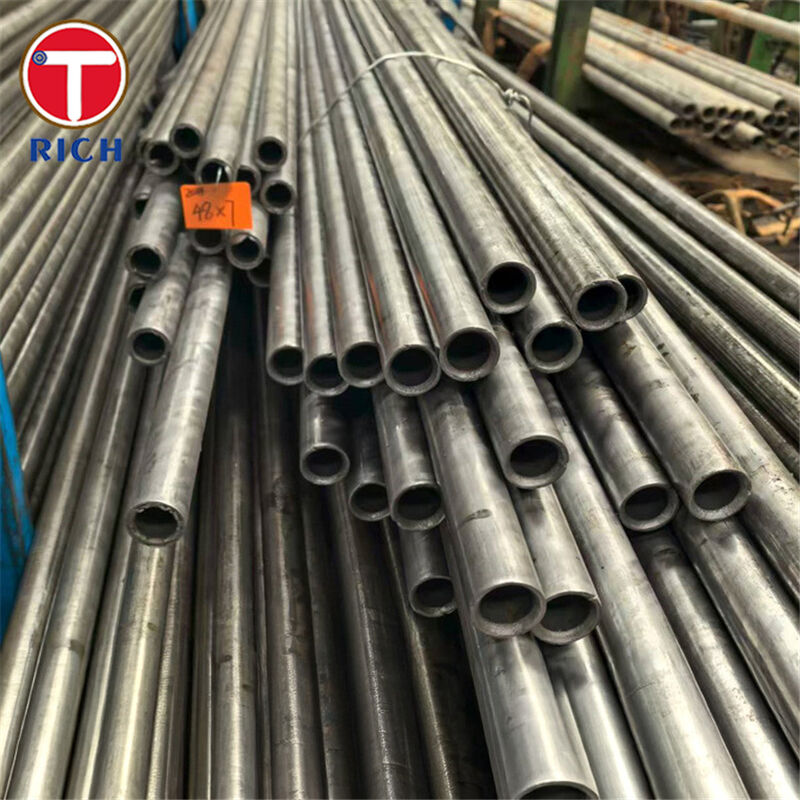

في هذا المنتج، يتم توفير 8617H على شكل أنابيب دقيقة غير ملحومة مسحوبة على البارد ومُحسَّنة خصيصًا لتحمل المكونات مثل الحلقات الخارجية والداخلية، والأكمام، والبطانات. يتم التعرف على هذه الدرجة على أنها فولاذ ذو جودة تحمل الكربنة وفقًا للمواصفات الدولية وسبائك يتم التحكم في قابلية التصلب، مما يجعلها مناسبة بشكل خاص لتطبيقات المحامل المضادة للاحتكاك.

2. المواصفات

الدرجة والتعيين

شكل المنتج

-

الأنابيب الميكانيكية غير الملحومة / الأنابيب الدقيقة

-

طريق التصنيع: تجاويف مثقوبة على الساخن، أو سحب على البارد، أو تشطيب بارد، تليها المعالجة الحرارية (المعيارية، أو المخففة من الإجهاد، أو المسقية والمخففة حسب الاتفاق مع العميل)

-

خصائص الأنبوب الدقيق: تفاوتات الأبعاد الضيقة والتحكم الأقصى في خشونة السطح بما يتماشى مع معايير الأنبوب الدقيق المعترف بها

نطاق الأبعاد (نموذجي، قابل للتخصيص)

-

القطر الخارجي: يصل إلى 380 مم تقريبًا للأنابيب غير الملحومة الدقيقة، اعتمادًا على المعيار المحدد وطريق التصنيع

-

سمك الجدار: من المقاطع ذات الجدران الرقيقة للأقفاص إلى الجدران الأثقل لتحمل الأكمام والحلقات

-

الأطوال: ثابتة أو عشوائية؛ خيارات القطع حسب الطول متاحة لمكونات المحمل

شروط التسليم

-

+C (مسحوب على البارد/صلب)

-

+LC (مسحوب على البارد/ناعم)

-

+SR (تخفيف التوتر)

-

+أ (ملدن)

-

+N (تطبيع)

-

Q+T (مروي ومخفف، بما في ذلك دورات تصلب الحالة حسب الحاجة)

خيارات العرض النموذجية

-

أنابيب مستقيمة لتصنيع الحلقات والأكمام

-

أنابيب على شكل شبكي تقريبًا لأغطية المحامل والبطانات الدقيقة

-

شهادات المواد EN 10204 3.1 أو 3.2 متاحة عند الطلب

3. الميزات الرئيسية

-

الأمثل للكربنة وتصلب القضية

-

يوفر الكربون في نطاق حوالي 0.14-0.20% مع النيكل والكروم والموليبدينوم صلابة ممتازة وعمقًا ثابتًا للعلبة بعد الكربنة.

-

يطور الفولاذ سطحًا عالي الصلابة لمقاومة التآكل والنقر، مع قلب قوي يمكنه تحمل الصدمات وأحمال الانحناء.

-

قلب متين ومرن لضمان موثوقية التحمل

-

دقة الأبعاد والسطح

-

تحمل نظافة الجودة

-

نافذة معالجة حرارية مرنة

4. مزايانا

4.1 "هل يمكنك ضمان عمق وصلابة علبة متسقة لتحمل السباقات؟"

نحن نستخدم 8617H كفولاذ محمل الكربنة مع كيمياء ونظافة وصلابة يمكن التحكم فيها ومناسبة لتطبيقات التحمل. يتم اختيار طرق المعالجة والمعالجات الحرارية لإعطاء نتائج موثوقة للكربنة أو نيترة الكربون، مع التحقق من عمق العلبة وصلابة السطح من خلال اجتياز الصلابة القياسية وعلم المعادن. يتم التحقق من صحة الصلابة الأساسية والخصائص الميكانيكية في كل حرارة أو دفعة ويتم توثيقها في شهادات اختبار المطحنة.

4.2 "كيف يمكنك التحكم في تحمل الأبعاد وجودة سطح الأنابيب؟"

يتم تصنيع أنابيبنا كمنتجات دقيقة مسحوبة على البارد وفقًا لمعايير الأنابيب الدقيقة المعترف بها. وهذا يضمن تفاوتات مشددة على القطر الخارجي وسمك الجدار، واستقامة جيدة، وأقصى قدر من خشونة السطح. يمكن توفير طحن أو شحذ إضافي عند الحاجة إلى تشطيبات سطحية فائقة الدقة قبل طحن المجاري المائية.

4.3 "هل الفولاذ نظيف بدرجة كافية لتحمل فترة حياة عالية؟"

نحن نقدم طرق صهر عالية النظافة مثل فرن القوس الكهربائي مع مغرفة التكرير والتفريغ الفراغي، وإذا لزم الأمر، إعادة صهر الخبث الكهربائي أو الحث الفراغي بالإضافة إلى إعادة الصهر. توفر هذه الطرق محتوى تضمين منخفض ومستويات منخفضة من الأكسجين مناسبة للفولاذ عالي الجودة. يمكن توفير تقييمات التضمين وتقارير النظافة لدعم متطلبات عمر إجهاد التلامس المتدحرج.

4.4 "هل يمكنك مطابقة المعايير الدولية حتى يمكن توحيد تصميمي وضمان الجودة؟"

يتماشى التركيب الكيميائي لـ 8617H مع المواصفات الأمريكية المستخدمة على نطاق واسع لكربنة سبائك الفولاذ مع نطاقات صلابة محددة. بالإضافة إلى ذلك، يمكننا توفير درجات تصلب الحالة الأخرى مثل SAE 8620، و20MnCr5، وSCM420H، وEN353 وإسنادها الترافقي بحيث يتمكن العملاء الذين يعملون تحت EN أو JIS أو GB أو GOST من اعتماد أقرب درجة مطابقة. يمكن اعتماد أبعاد الأنبوب الدقيقة والخواص الميكانيكية في وقت واحد وفقًا لمعايير ASTM وEN وJIS وGB ذات الصلة حسب الحاجة.

4.5 "ماذا عن الخدمات اللوجستية، وموك، وإمكانية التتبع؟"

نحن ندعم كميات الطلب المرنة، بدءًا من الدفعات التجريبية لتطوير المحامل الجديدة وحتى الإنتاج بكميات كبيرة لبرامج السيارات. يتم الحفاظ على إمكانية التتبع الكامل للحرارة إلى القطعة، مع وضع علامة واضحة على الحزم والأنابيب على النحو المتفق عليه. يمكن أن يشمل التوثيق شهادات المواد، وتقارير الاختبارات غير المدمرة، ونتائج فحص الأبعاد، وسجلات المعالجة الحرارية.

5. التركيب الكيميائي

| درجة |

مثال قياسي |

ج |

سي |

من |

كر |

ني |

شهر |

"الآخرون" النموذجيون (الحد الأقصى، بالوزن%) |

| 8617هـ |

الصلب الكربنة ASTM/SAE |

0.14-0.20 |

0.15-0.35 |

0.60-0.95 |

0.35-0.65 |

0.35-0.75 |

0.15-0.25 |

P ≥ 0.025، S ≥ 0.015، Cu ≥ 0.30، Al ≥ 0.05، O ≥ 0.002 |

| ساي 8620 |

سبائك الصلب SAE/ASTM |

0.18-0.23 |

0.15-0.35 |

0.70-0.90 |

0.40-0.60 |

0.40-0.70 |

0.15-0.25 |

ف ≥ 0.035، ق ≥ 0.040 |

| 20MnCr5 |

EN 10084 الفولاذ المتصلب للعلبة |

0.17-0.22 |

≥ 0.40 |

1.10-1.40 |

1.00-1.30 |

— |

— |

ف ≥ 0.025، ق ≥ 0.010 |

| SCM420H |

سلسلة JIS SCM |

0.17-0.23 |

0.15-0.35 |

0.55-0.95 |

0.85-1.25 |

≥ 0.25 |

0.15-0.30 |

ف ≥ 0.030، ق ≥ 0.030، النحاس ≥ 0.30 |

| EN353 |

الفولاذ المقاوم للصدأ بدرجة BS/EN |

0.10-0.20 |

0.10-0.35 |

0.50-1.00 |

0.75-1.25 |

1.00-1.50 |

0.08-0.15 |

ف ≥ 0.040، ق ≥ 0.040 |

6. الخواص الميكانيكية

| درجة |

مثال قياسي |

الحالة النموذجية (الأساسية) |

قوة الشد Rm (MPa) |

قوة الخضوع Rp0.2 (MPa) |

استطالة أ (٪) |

الصلابة الأساسية النموذجية* |

| 8617هـ |

فولاذ على شكل حرف H ASTM/SAE |

مروي وخفف |

≥ 861 |

≥ 748 |

~24 |

~ 421 HBW (قيمة ورقة البيانات) |

| ساي 8620 |

سبائك الصلب SAE/ASTM |

مروي ومخفف أو مكربنة الأساسية |

~650-880 |

~350-550 |

~8-25 |

~ 200–300 HB (أساسي، نموذجي) |

| 20MnCr5 |

EN 10084 تصلب الحالة |

مروي ومخفف أو مكربنة الأساسية |

~650-880 |

~350-550 |

~8-25 |

~ 200–300 HB (أساسي، نموذجي) |

| SCM420H |

سلسلة JIS SCM |

مروي وخفف |

~542–650+ |

~345+ |

~12-20 |

~ 140–280 HBW (حسب الحالة المزاجية) |

| EN353 |

تصلب الحالة BS/EN |

مروي وخفف |

~ 700-850 |

~300-450 |

~16–20 (تصل إلى حوالي 46% في بعض أوراق البيانات) |

~ 190–380 HB (اللب، قبل وبعد التصلب النهائي) |

7. المعايير المطبقة

أستم / ساي

-

معايير الأنابيب الميكانيكية غير الملحومة وأنابيب السبائك للأنابيب الدقيقة

-

معايير سبائك السبائك التي يتم التحكم فيها من حيث الصلابة للفولاذ ذو النطاق H مثل 8617H

-

كربنة الفولاذ للمحامل المضادة للاحتكاك

-

مواصفات شريط ولوحة سبائك الصلب العامة

EN (أوروبا)

جيس (اليابان)

جيجابايت (الصين)

غوست (روسيا / رابطة الدول المستقلة)

8. مجالات التطبيق

مجالات التطبيق العامة

-

محامل المتداول ومكونات تحمل

-

أجزاء نقل الحركة وعلبة التروس

-

مكونات مجموعة القيادة للسيارات والطرق الوعرة

-

أجزاء الهندسة الميكانيكية العامة المعرضة للصدمات والانحناء والتحميل الدوري

استخدامات محددة في قطاع المحامل

-

حلقات تحمل داخلية وخارجية يتم تشكيلها من أنابيب دقيقة ومن ثم يتم كربتها وطحنها

-

الأكمام الحاملة والأكمام المحولة حيث يكون سمك الجدار الدقيق والاستدارة أمرًا مهمًا

-

تجمع أغلفة المحامل والبطانات بين سعة التحميل الشعاعية والمحورية مع الاتصال المنزلق أو المتدحرج

-

محامل الدعم لعلب التروس، وتجميعات المحاور، والناقلات التفاضلية، ووحدات نقل الطاقة المماثلة

س: هل أنت شركة تجارية أو الشركة المصنعة؟

ج: الشركة المصنعة، ويمكن أيضا القيام بالتداول.

س: كم من الوقت هو وقت التسليم الخاص بك؟

ج: بشكل عام، من 10 إلى 15 يومًا إذا كانت البضاعة في المخزون، أو من 30 إلى 40 يومًا إذا لم تكن البضاعة في المخزون،

هو حسب الكمية.

س: هل تقدمون عينات؟ هل هو مجاني أم إضافي؟

ج: نعم ، يمكننا تقديم العينة مجانًا ولكن نحتاج إلى دفع تكلفة الشحن.

س: ما هي شروط الدفع الخاصة بك؟

ج: الدفع <= 2000 دولار أمريكي، 100% مقدمًا. الدفع> = 2000 دولار أمريكي، 30% T/T مقدمًا، الرصيد قبل الشحن.

إذا كان لديك سؤال آخر، الثابتة والمتنقلة لا تتردد في الاتصال معي.

يجب أن تكون رسالتك بين 20-3000 حرف!

يجب أن تكون رسالتك بين 20-3000 حرف! من فضلك تفقد بريدك الالكتروني!

من فضلك تفقد بريدك الالكتروني!  يجب أن تكون رسالتك بين 20-3000 حرف!

يجب أن تكون رسالتك بين 20-3000 حرف! من فضلك تفقد بريدك الالكتروني!

من فضلك تفقد بريدك الالكتروني!